Hi rock stars,

Many thanks to the thoughtful, smart suggestions in Name that component!, from Kyle, David, AdamT, Kyle@otyp, and Ben. All together, we worked through the panini/linkage idea, browsed camera shops to find ball joints, and really set out to get the best design that’s easy to build. That said, it can be impossible to find off the shelf parts to bring a new design to reality. More specifically, I’ll say that my current source for searching (McMasterCarr) has lots of really *big* things, lots of door hinges or refrigerator hinges, but not so much in the *small* side of things. Is there a good source for electronics-sized components that you like? Digikey and Mouser stick to electronics components, what I’m wondering about is a digikey+mcmaster love child. Of course, this will be helped in the near future with the rise of 3D printing and Makerbots, where small batches of custom parts start to make sense. Maybe a Makerbot is in my future.

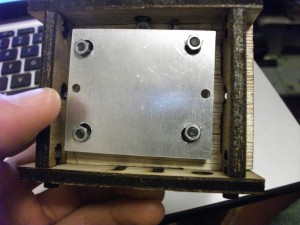

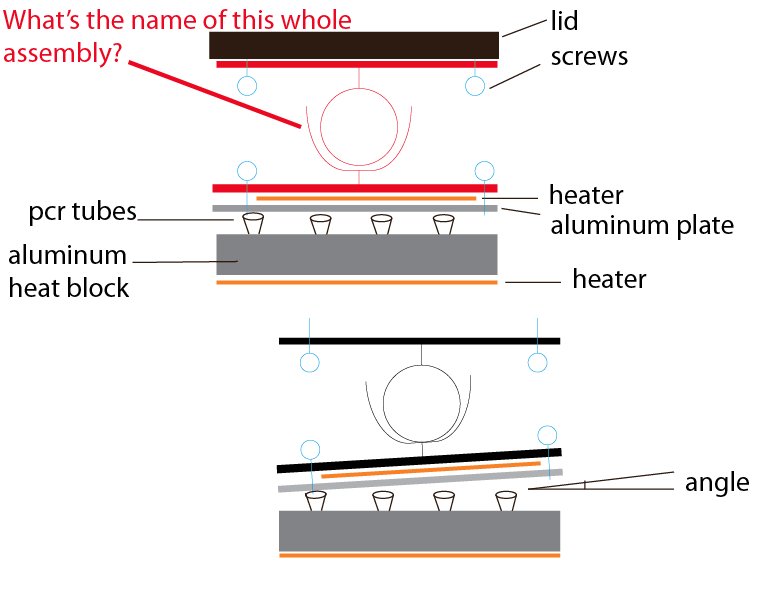

The best design turned out to be the most simple one, suggested by AdamT — 4 springs pushing down the aluminum plate, the whole assembly floats on 4 bolts. The lid gets locked down into a low position, and the springs/hinge float around as needed. I prototyped it up, showed Josh, and we like it. We’re going to be mounting a heater and really testing it out over the next few weeks.

2 opportunities for improvement are:

- how to lock the lid in the “down” position (magnets would be great, a bolt with a thumb screw is more realistic).

- Secondly, the nuts/bolts in the picture are metal and heat up a lot. I’m planning onfinding nylon screws (M3), though their operating temperature is 85C (the lid is heated at 100C to 110C, the melting point of nylon is over double that). Suggestions welcome :)

(Skinny shoulder screws/binding barrels would be nice so that the plate can slide easily up and down except I need 2 nuts on each bolt, one nut to hold the bolt in place at its base, the other nut to keep the aluminum plate/spring on. A bolt with threads at the beginning and end but not the middle would be good.)

Thank you to everyone!

Tito